RCM Y-wall can be used as an external sheathing board on structures including where a fire rating is required including those greater than 18m in height, where a structure is over 18m in height RCM Y-wall should be used from ground level all the way up the structure.

-

Fire rated to EN 13501-1 class A1

-

2400 x 1200mm (6mm, 9mm, 12mm and 15mm) Other board sizes are available

-

Key Applications

- Fire rated sheathing board

- OEM applications for improved strength and density

- Recommended for buildings above 18m

- Ideal for Offsite Construction Regimes

Features

- Fire rated to EN 13501-1 class A1

- BBA approved

- Flexible and strong

- Excellent water resistance

- Easy to use

- High levels of dimensional stability

- Integrates with other RCM products

Workability

RCM Y-wall can be cut, drilled and nailed using conventional hand tools; offering many of the properties of timber.

For cutting the product in any volume, we recommend the use of an RCM polycrystalline diamond Dart Blade to avoid excessive wear on other blades. Alternatively, RCM offer a complete fabrication service, find out more.

Technical Request Form

Do you want more detailed info on our products for your project ?. Reach out directly to our technical team. Just fill out our straightforward form, and we’ll get on it. Let’s make things happen together!

Technical Request FormFind us locally

We have a national network of trained cladding specialists on hand to help you with your project, find your local sales representative here .

Customer Facing Contacts

Y-Wall as part of a system build-up

Technical Data

Nominal Density

1200 kg/m3

Bending Strength

((Modulus of Rupture))12 N/mm2

Modulus of Elasticity

((MoE))4000 N/mm2

Thermal Conductivity

≤0.23 W/mk

Moisture Content

≤9%

Reaction to Fire

BS EN 13501-1 Class A1 Non-Combustible

Biological Resistance

Highly Resistant

Surface Condition

Front Face - Smooth

Back Face - Textured

Durability

((Life Expectancy - Minimum))30 years

Standard Board Sizes

2400 x 1200mm

Thickness

((mm))6, 9, 12, 15

Nominal Mass of Product

((kg/m²))7.2, 10.8, 14.4, 18

Dimensional Tolerance

Length

±3mm

Width

±3mm

Thickness

±0.5mm

Product Testing and Certification

Fire Reaction Tests

BS EN 13501-1:2018 Class A1

BS EN ISO 1716:2018

BS EN ISO 1182:2020

BS EN 1363-1

BS EN 1364-1

BS EN 1365-1

BS 476 Part 4

BS 476 part 22 fire rated through wall solutions

Physical Properties

BS EN ISO 12467

BS EN 594 Category 1

BS EN ISO 1015-11

BS EN ISO 1062-1

BS EN 594:2011

Recommended Fixing

Steel Frame

FIX006 - 4.8mm x 38mm Wing tip self drilling fixing

Timber Frame

FIX005 - 4.2mm x 42mm Climaseal self drilling fixing

Y-Wall FAQs

RCM Y-wall is rated as A1 non-combustible.

No, RCM Y-wall cannot be left permanently exposed.

RCM Y-wall has one smooth face and one textured face, the smooth face should be fixed outermost.

RCM Dafa tape should be applied to all board to board joints as soon as possible after fixing the boards, unless an airtight seal is required to the external face of the sheathing board, for an airtight seal then the RCM Joint Seal system should be used.

If the joints are taped using RCM Dafa tape as soon as the boards are fitted they can be left exposed during the construction phase for twelve months.

RCM Y-wall edge distance is 15mm except at the board corners where fixings should be moved up or down to achieve 50mm. Fixings should be fixed using a maximum 600mm x 300mm grid pattern.

- 27 No. fixings per 2400mm x 1200mm sheet when fixed in a vertical orientation.

- 25 No. fixings per 2400mm x 1200mm sheet when fixed in a horizontal orientation.

- For fixing into SFS framing 4.8mm x 38mm self-drilling wingtip fixings suitably treated against corrosion should be used.

- For fixing into Timber framing 4.2mm x 42mm self-drilling fixings suitably treated against corrosion should be used.

We have done our own in-house testing for 12mm RCM Y-Wall. The results suggest a radius of 7.5m or greater, however a structural engineer should ratify this for your project. RCM Y-Wall should not be fixed to a radius but should be cut into vertical strips and fixed to form the curve from a series of flat panels.

RCM can supply Poly Crystalline Diamond (PCD) blades suitable for cutting RCM Y-Wall in a range of diameter and bore sizes, please contact RCM Technical department for further information.

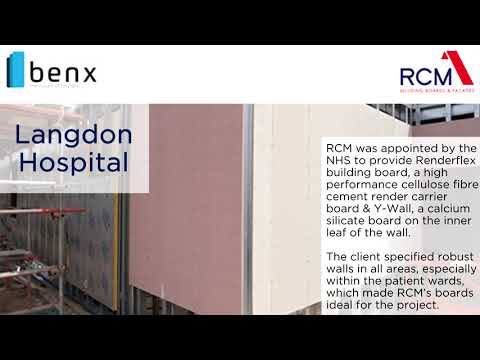

Riverlight Case Study

London

During the early 19th Century, a large section of the South Bank of the River Thames, London, comprised small wharves, docks and other industrial uses. In more recent years, the site has been used as a...

Download the Y-Wall Fact Sheet

Find out about Y-wall, a high-quality flexible calcium silicate based fibre cement building board, perfect for use as an A1 fire rated sheathing board.

Y-Wall Technical Information

- Y-Wall Air Tightness Substantiation Sheet

- Y-Wall Compressive Strength Substantiation Sheet

- Y-Wall Fire Substantiation Sheet 12mm 120 Minutes 5206

- Y-Wall Fire Substantiation Sheet 12mm 120 Minutes 5207

- Y-Wall Fire Substantiation Sheet 12mm 90 Minutes

- Y-Wall Fire Substantiation Sheet 9mm 120 Minutes

- Y-Wall Fire Substantiation Sheet 9mm 60 Minutes

- Y-Wall Racking Resistance Substantiation Sheet

- Y-Wall Racking Resistance Substantiation Sheet 5224

RECOMMENDED COMPONENTS AND ACCESSORIES

Y-Wall Videos

Y-Wall Product Features

Y-Wall Case Study

Y-Wall Case Study