-

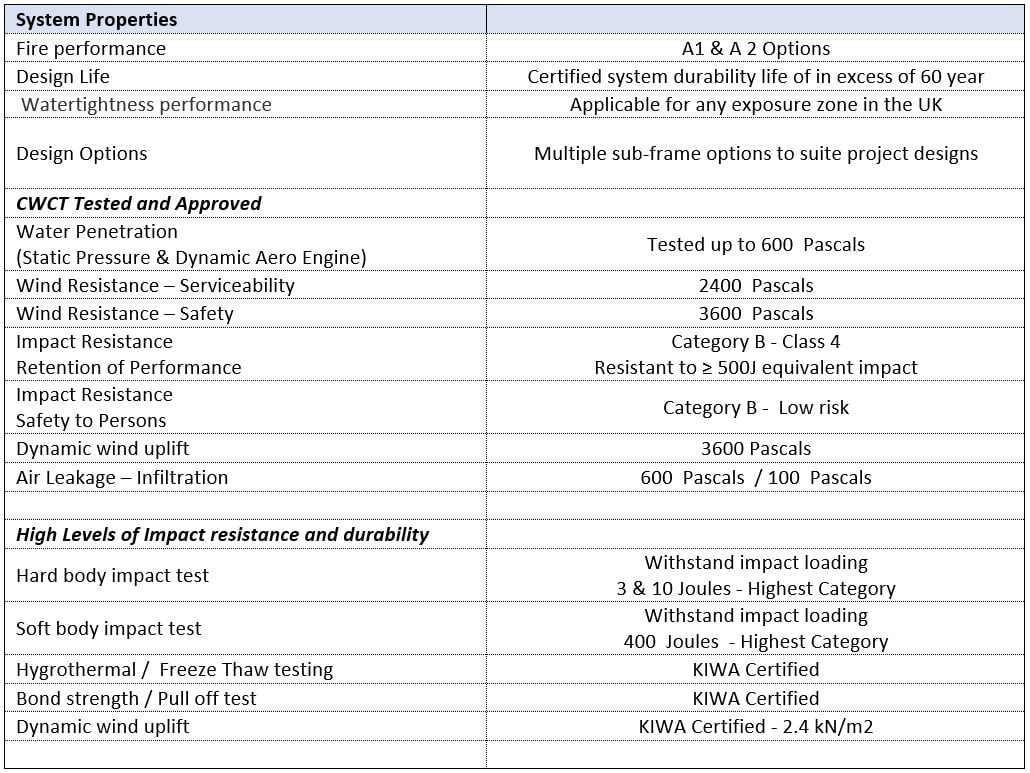

A1 or A2 Fire Classification to BS-EN-1350, depending on system configuration.

-

KIWA BDA Certificate

CWCT Tested -

Timber frame (Limited to 18m) with insulation as per project specification

SFS (Up to and above 18m) with insulation as per project specification

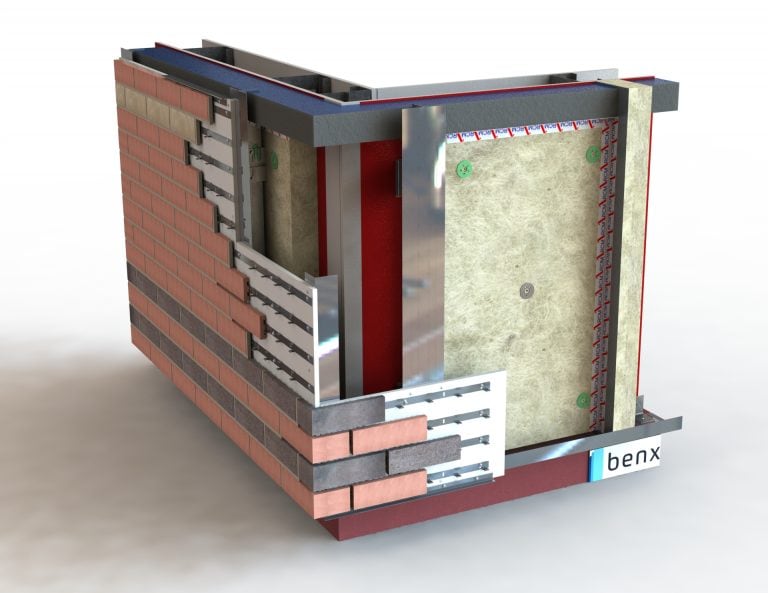

Benx RCM Y wall Sheathing Board (A1 calcium silicate) to Primary Frame

Self-Adhesive Breather Membrane

EPDM membranes to all openings

Insulation as per Benx project specification (subject to support frame type)

System fixings, trims, etc as per Benx Specification -

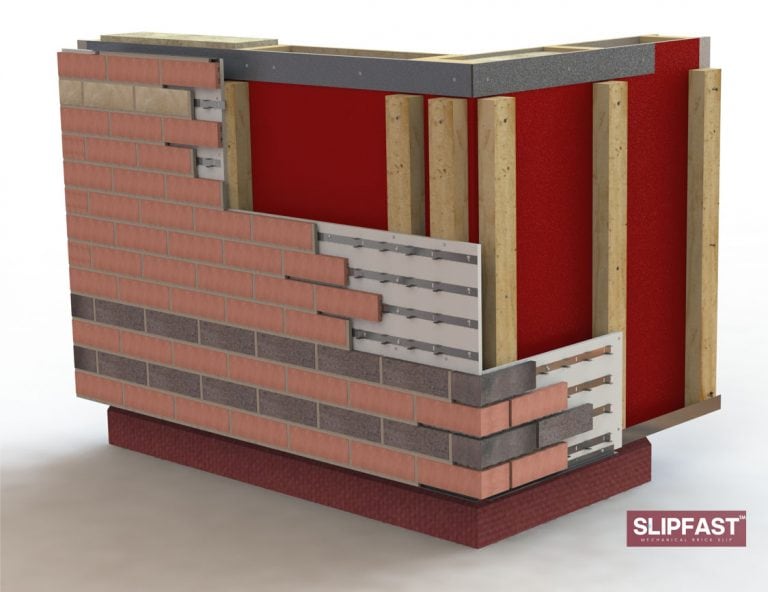

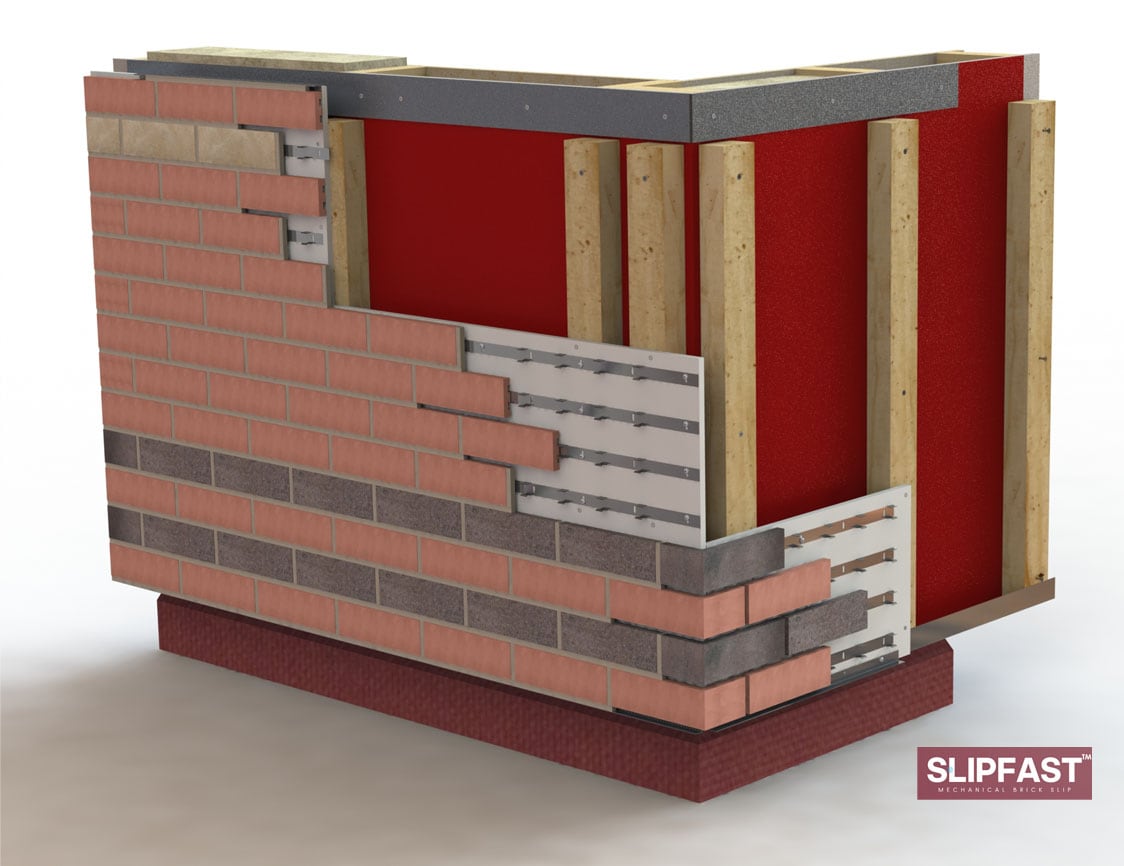

Slipfast® is our highly versatile, lightweight yet strong, real brick cladding system offering many cost and time benefits. This factory produced brick carrier system is supplied direct with pre-installed rails, ready to receive pre-formed clay brick-slips, which are then pointed and sealed on site (no adhesive needed). The system includes flexible deign features to allow simple detailing at building headers, corners, and openings.

Harness the benefits of offsite construction

The installation of our prefabricated Slipfast® system is much easier and less dependent on weather conditions than traditional brickwork, which substantially shortens installation times and related cost.

Highly Versatile, energy efficient system

The Slipfast® system can be applied with different mounting options similar to our other rain screen systems. It provides a high performance façade and improves a building’s overall energy efficiency.

Combines the aesthetics and durability of fired clay bricks

Slipfast® exhibits the timeless traditional beauty of fired clay brick, yet also makes full use of its durability and strength as a premium exterior wall material.

Technical Request Form

For Technical Service or Product Support please file a technical request using our support form or contact your local representative.

Technical Request FormContact Us

Can’t find the solution you’re looking for? We can help. Our team of experts are on hand to answer your questions.

Contact UsTypical System Build-Up

Download the SLIPFAST® Brochure

Discover more about our new mechanically-fixed brick slip system.

Slipfast® Installation

Certification and Test Data

Slipfast® addresses all the vital elements of product specification.

Based on an entirely new design we have focussed on ensuring peerless performance in several key areas: versatility, weight, robustness, non-combustibility, speed of build, thermal efficiency whilst still maintaining an aesthetic appeal.

Furthermore, to ensure versatility, the system is available in multiple panel sizes to suit your requirement*.

Not only does this ensure design flexibility it also presents an outstanding value proposition when compared to competing systems.

* Subject to minimum quantity orders

Technical Details

- Slipfast – Timber Batten – Cill Detail

- Slipfast-Coping detail-Timber Battens

- Slipfast – Timber Batten – External Corner

- Slipfast – Timber Batten – Horizontal movement Joint

- Slipfast – Timber Batten – Starter Track

- Slipfast – Timber Batten – Window Head

- Slipfast – Timber Batten – Window Jamb

- Slipfast – Helping Hand With Insulation-Coping

- Slipfast – Helping Hand With Insulation-Cill Detail

- Slipfast – Helping Hand With Insulation-External Corner

- Slipfast – Helping Hand With Insulation-Horizontial Movement Joint

- Slipfast – Helping Hand With Insulation-Starter Track

- Slipfast – Helping Hand With Insulation-Window Head

- Slipfast – Helping Hand With Insulation-Window Jamb

FULL SYSTEM FLEXIBILITY : DESIGN OPTIONS FOR INSTALLERS

The Slipfast system is available with a variable range of sub frames within our Agrément approval including the following options

• Timber battens

• 25mm A1 Metal top hat profile

• A1 Allface Aluminium support frame ( multiple cavity depth options)

The certified range of options provide clients with one of the most flexible approaches to system build up on timber of metal framed structures. In addition to this, the Slipfast system can be fixed in varying ways back to the primary structure.

SYSTEM 1 : Support Frame location flexible (A2 Fire resistance)

This Slipfast system can be fixed either through to the primary studs at no greater than 600mm centres, but also has the option for the battens or top hat to be fixed back to a suitable RCM sheathing board if stud locations (no greater than 600mm centres) do not always allow panel sizes to align with stud locations.

This flexible approach allows the specifier or contractor to not have to add additional primary studs to support the Slipfast system if not required for the main structure.

• Precoated panels available in a range of sizes with stainless steel mechanical rails and clips already attached to panel.

• Panel edges are square edge and do not require interlocking.

• All rails, clips and fixings stainless steel for maximum durability

• Rails and clips can be adjustment on site for alignment adjustment if required.

• Panel length available in either 600mm or brick size variations. Panel heights align to brick courses.

SYSTEM 2 : Support frame fixed at max. 600mm centres (A1 or A2 Fire Resistance)

This system is fixed back to our Allface Support Frame and provides the system with an extensive range of cavity depth variables.

• Precoated panels available in a range of sizes with stainless steel mechanical rails and clips already attached to panel.

• Panel edges are square edge and do not require interlocking.

• All rails, clips and fixings stainless steel for maximum durability

• Rails and clips can be adjustment on site for alignment adjustment if required.

• Panel sizes are available in a range of options, however the Allface support frame is always fixed back through to the primary studs.

Clay fired brick finishes and colours

Slipfast brick slips are more precise, lighter and thinner than other moulded brick slips while still retaining the timeless quality of a clay product. We have a large range of brick slip colours available which are in keeping with those traditionally found in the UK. Our brick slips are manufactured to BS EN 771-1 using traditional British firing methods using locally sourced clays.

Slipfast bricks are purpose made clay slips, manufactured on dedicated extrusion machines. These purpose made clay brick slips have an average 70% less embodied carbon than single faced cut slips just in terms of firing them. Furthermore there is virtually no waste in their manufacture and nearly all process waste is re-used during manufacture.

Additionally, there is less water consumption per slip due to the products thin profile compared with cut slips.

To ensure consistency and continuity of supply, we have the flexibility to control recipes, texturing rollers, firing temperatures and kiln conditions.