Bromsgrove Street

Birmingham

88 Bromsgrove Street is a 140-bed luxury student accommodation perfectly located for anyone studying...

SPSenvirowall silicone render and clay brick slips has been specified for this contemporary new build on a popular Caerleon Road area of Newport, formerly the site of St Matthews Church. The façade system...

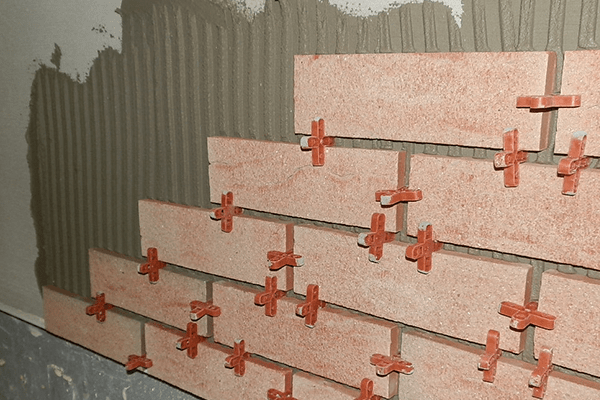

The area that is to be covered with BrickStick should be marked out evenly with chalk lines. Door lintels and windows should be used as starting points. A starting track can be used to provide a level line to work from. Installation should start from a pistol slip corner.

A small amount of adhesive should then be troweled applied to the wall. Only as much adhesive as can be immediately covered with slips should be applied, a notched trowel should be combed through the adhesive before the brick slip is applied. Slips can be easily cut on site using a diamond tipped angle grinder.

Starting above the first course of brick work a 10mm 3 braid nylon rope is inserted into the horizontal joints, this will create a natural looking 10mm mortar joint. The rope will accommodate for any natural bend in the brick work creating the look of a traditional brick built wall. A small piece of rope can be cut to provide a guide for the vertical joints.

After initial setting the rope can then be gently removed. The joints can then be filled with a sand/cement mortar and smoothed using a pointing trowel. For speed of application a mortar pointing gun should be used. Any excess mortar can be brushed off once it has dried.